CLOUDROAD

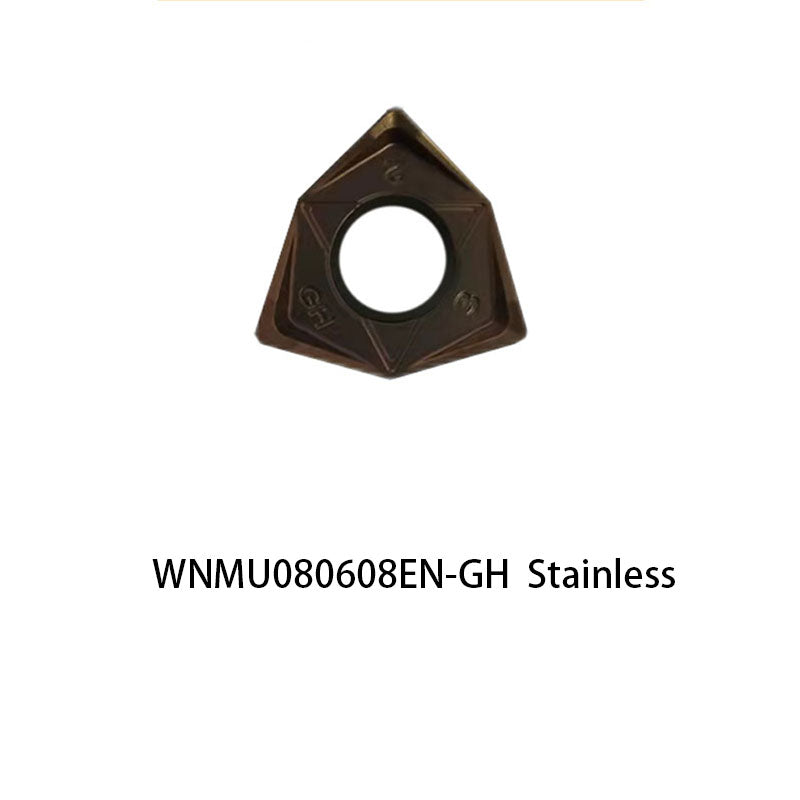

LNMU0303 fast feed milling cutter Toshiba WNMU CNC steel stainless steel blade

MODEL

LNMU0303 fast feed milling cutter Toshiba WNMU CNC steel stainless steel blade

LNMU0303ZER-ML Universal 10pcs

Shop location

101-102 Fujian Street 101-102, Building 28, Fujian Street, Wuzhou International Industrial Expo City Phase I Wuxi

214111 Jiangsu

China

Choose options

MODEL

MODEL

The blade is processed using German technology, with stronger overall hardness, sharper edges, greater wear resistance, and longer lifespan.

Specially designed for steel parts, with high hardness, sharpness, wear resistance, durability, and high smoothness.

Made with added hardness, the highest processing hardness can reach 62 degrees. The most important factor in workpiece processing is accuracy, which is determined by the cutting tools. Exquisite patterns can make chip removal smoother.

Shipping is typically free for most orders. However, in remote areas, shipping costs may vary depending on the delivery location, order weight, and chosen shipping method. The exact shipping cost will be calculated and shown during checkout. Please note that international orders may be subject to additional customs duties and taxes, which are the responsibility of the customer. Please contact your local customs office for more information.

Pack

We pack all products following standardized procedures to ensure they are shipped according to our high-quality standards. We make every effort to ensure your product arrives safely at your home.

We have a 30-day return policy, which means you have 30 days after receiving your item to request a return.

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method within 10 business days. Please remember it can take some time for your bank or credit card company to process and post the refund too.

If more than 15 business days have passed since we’ve approved your return, please contact us at Lily@yl-cnc.com.