CLOUDROAD

STFCR STFCL RPA spring steel anti-seismic tool holder CNC tool holder with deep end face groove for large cutting

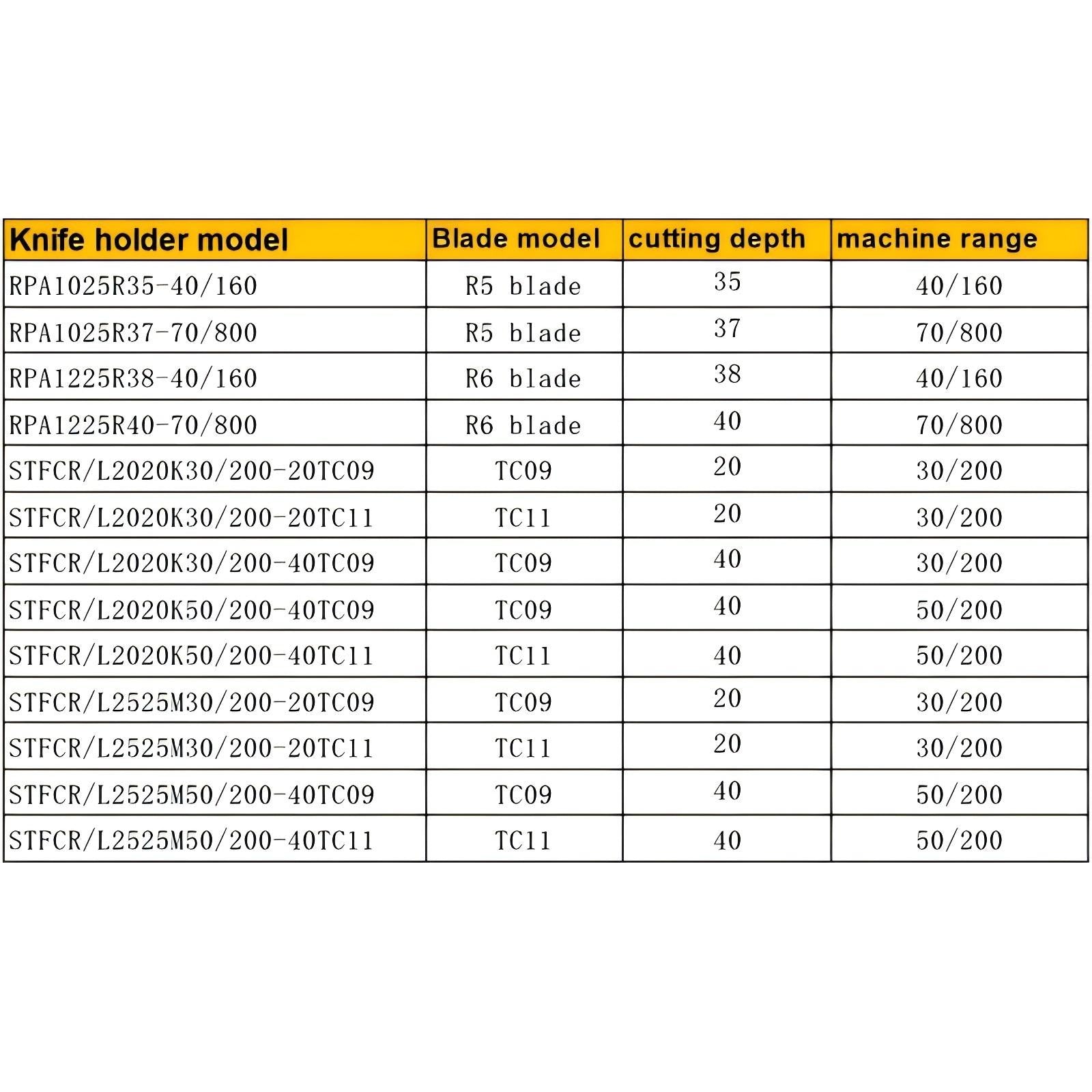

MODEL

STFCR STFCL RPA spring steel anti-seismic tool holder CNC tool holder with deep end face groove for large cutting

RPA1025R35-40/160

Shop location

101-102 Fujian Street 101-102, Building 28, Fujian Street, Wuzhou International Industrial Expo City Phase I Wuxi

214111 Jiangsu

China

Choose options

MODEL

MODEL

• Multi-stage vibration reduction technology: The cutter body is made of H13 high-rigidity steel (hardness ≥ 55°), combined with an arc-shaped anti-vibration structure that optimizes weight distribution, which significantly suppresses processing vibration and is especially suitable for long overhang deep groove processing;

• Modular tool bar system: The dual series of STFCR (positive tool)/STFCL (reverse tool) covers 20/25mm square shank specifications, adapting to the bidirectional clamping requirements of lathes and machining centers, and coping with complex blind hole/through hole scenarios.

• Ultra-deep groove processing: The maximum cutting depth is 40mm (such as the STFCR2020K 50/200-40T11 model), supporting single-tool deep groove milling of traditional multi-pass processes, and improving efficiency by more than 50%;

• Direct inclined surface processing: The unique cutting geometry design allows direct grooving on a 30° inclined surface without pre-processing the guide surface.

Shipping is typically free for most orders. However, in remote areas, shipping costs may vary depending on the delivery location, order weight, and chosen shipping method. The exact shipping cost will be calculated and shown during checkout. Please note that international orders may be subject to additional customs duties and taxes, which are the responsibility of the customer. Please contact your local customs office for more information.

Pack

We pack all products following standardized procedures to ensure they are shipped according to our high-quality standards. We make every effort to ensure your product arrives safely at your home.

We have a 30-day return policy, which means you have 30 days after receiving your item to request a return.

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method within 10 business days. Please remember it can take some time for your bank or credit card company to process and post the refund too.

If more than 15 business days have passed since we’ve approved your return, please contact us at Lily@yl-cnc.com.